A precisely manufactured code contained within a shell.

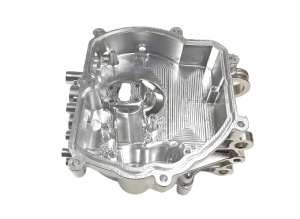

When this gleaming metal casing appeared, it resembled more of an industrial work of art—smooth cavities, intricate reinforcing ribs, and precisely positioned mounting holes; every detail was a miniature battlefield of precision manufacturing.

When this gleaming metal casing appeared, it resembled more of an industrial work of art—smooth cavities, intricate reinforcing ribs, and precisely positioned mounting holes; every detail was a miniature battlefield of precision manufacturing.

It was most likely the core casing of a car transmission or an aircraft hydraulic system: the complex internal chambers had to accommodate gears and oil passages, and the bolt holes on the outer wall needed to fit seamlessly with other components. Even a 0.01 mm error could lead to oil leaks, abnormal noises, or even system failure.

Such parts typically undergo a complete process of “aluminum alloy die casting – five-axis CNC precision machining – laser inspection”: the die casting process requires controlling the mold temperature difference within ±2℃ to prevent casting defects; during CNC machining, the high-speed spindle must maintain a feed accuracy of 0.005 mm between complex curved surfaces, while high-pressure cutting fluid is used to flush away aluminum chips to prevent tool jamming; finally, a coordinate measuring machine scans more than 200 points to ensure that every dimension falls within the tolerance range.

This seemingly cold metal casing is actually an “aggregate” of countless manufacturing details—from the control of raw material composition to the micron-level adjustment of machine tools, and the light precision of testing equipment, the meticulous attention to detail in every link is what supports the reliability of industrial products.