What is Sheet Metal Fabrication?

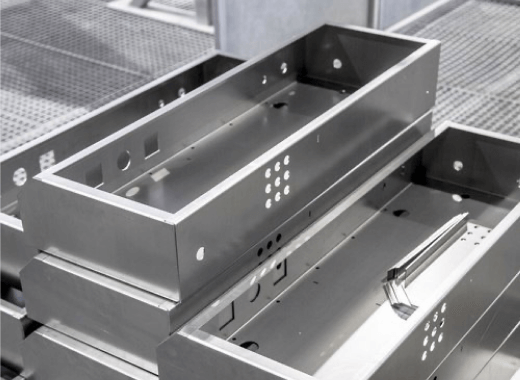

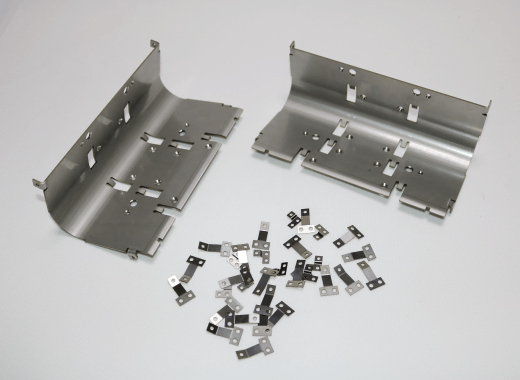

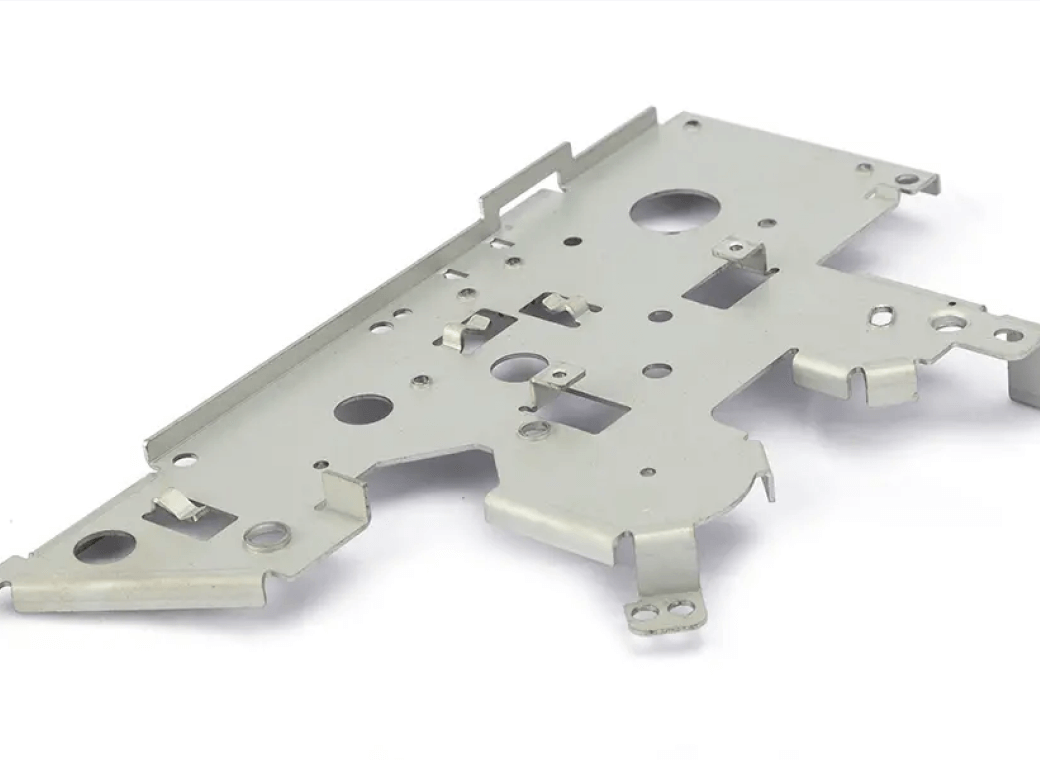

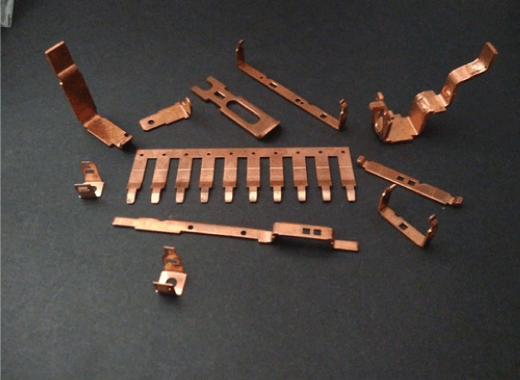

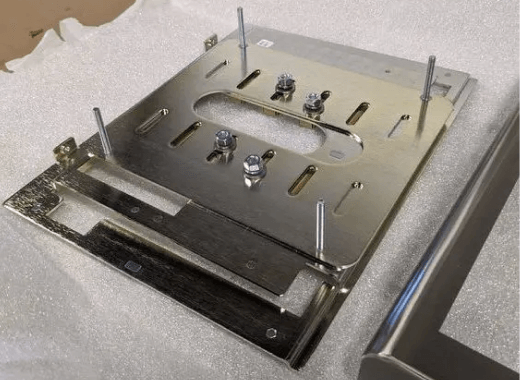

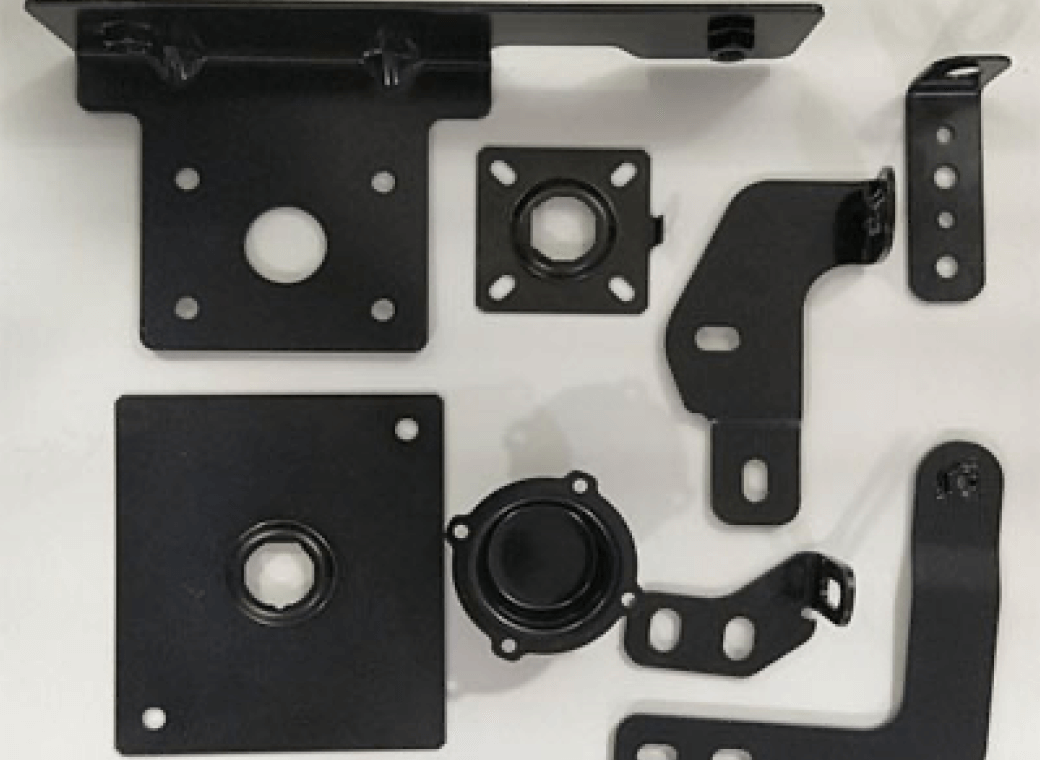

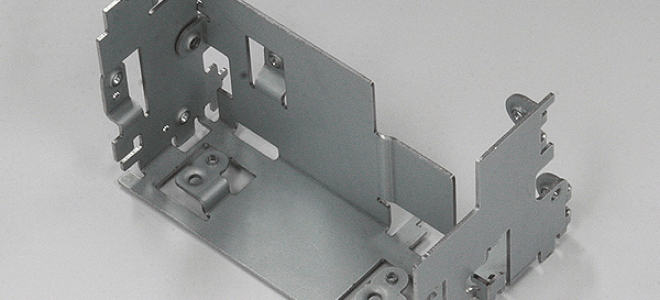

Sheet Metal Fabrication is the process of turning flat sheets of steel or aluminum into metal structures or products, by cutting, punching, folding and assembling. Sheet metal can be cut, bent or stretched into nearly any shape.

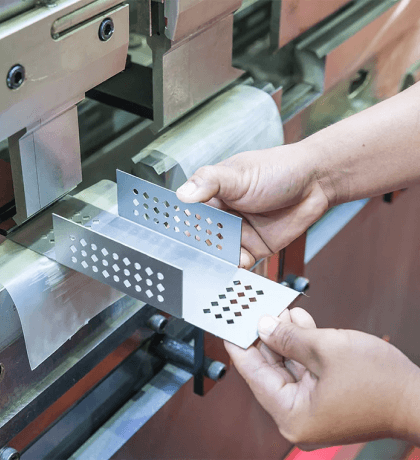

Sheet metal fabrication uses press brakes, which ease the process, by helping to create sharp bends and angles within the metal. There are a variety of different press brakes, which have different functions and are used for different purposes. One of the other main factors in sheet metal fabrication is welding. Once all the components are formed, they are then assembled and tack welded into position. Many welding techniques can be used in sheet metal fabrication in order to prevent warping or any other abnormalities.

RIX Sheet Metal Fabrication

Sheet Metal Fabrication is a valuable prototyping and production method for making robust functional parts like panels, brackets, and enclosures. Whether you need one single functional sheet metal prototypes or complete assembled sheet metal products(one set or hundreds sets ), We offers an affordable and super quality solution for your manufacturing needs. We have the full capability to handle every stage of your sheet metal fabrication projects, including bending, lasering, cutting, punching, welding, stamping, assembly and other precision sheet metal manufacturing processes.