RIX Rapid Prototyping

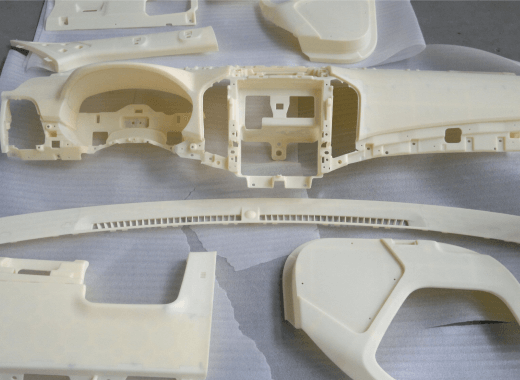

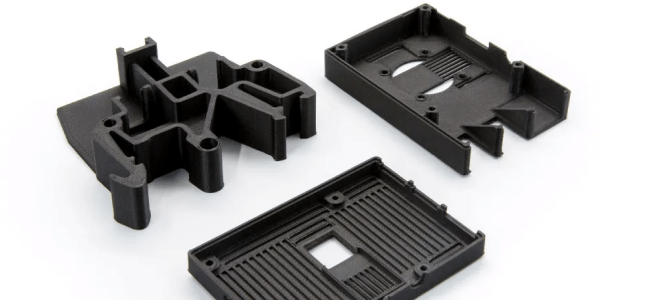

3D Printing

3D Printing is the most common way to make prototypes. It only takes a short time to make your design, if your 3D file is built, it might only need 24 hours for us to finish the part and complete the inspection, which really gives designer more time to consider and test his/her designs. For now, we can provide SLA/SLS/FDM services.

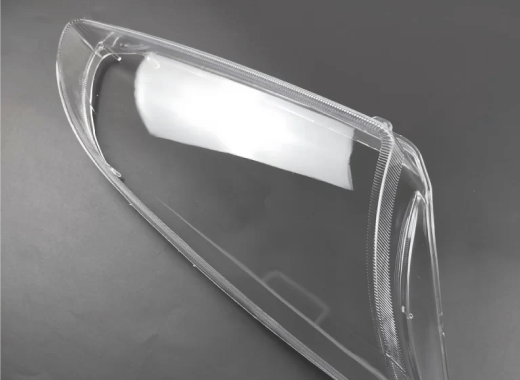

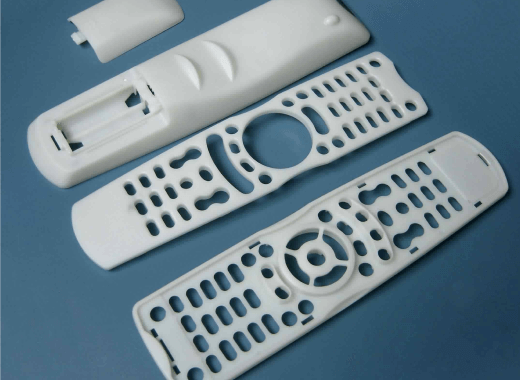

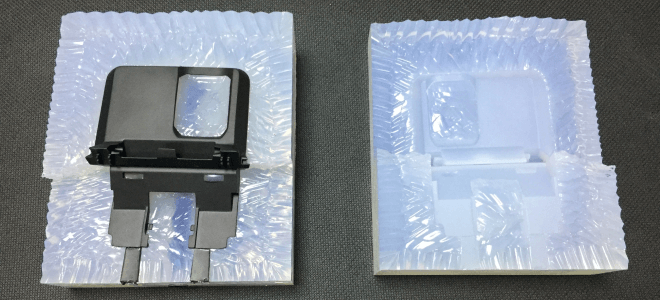

Vacuum Casting

Vacuum casting (urethane casting) is an economical alternative to low-volume injection parts. Generally, molds are made from silicone and use CNC Machining or SLA to make a master piece to casting for. These molds duplicate intricate details and textures and give consistent finishes from one part to the next. Materials are similar to engineering production plastics, such as ABS, PMMA, PC, PP, PA, and so on. Surfaces varied from transparent, translucent to colored, and from soft rubber to hard plastic.

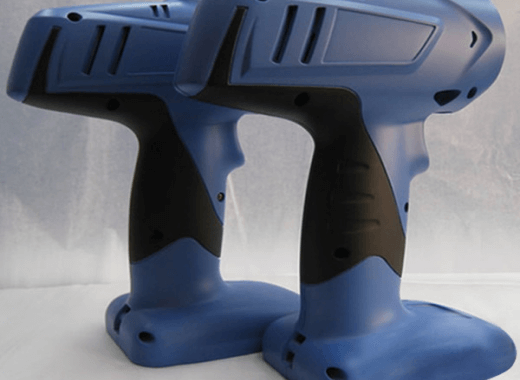

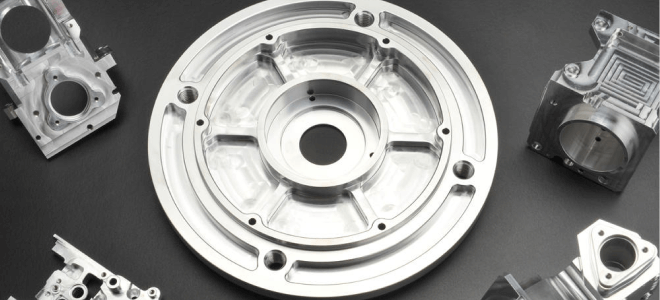

CNC Machining

CNC Machining services includes CNC Milling, CNC Turning, CNC Lathing, CNC Drilling and CNC Cutting. We do Milling and Turing most. CNC Milling is a precision machining in which a cutter removes material by moving into the workpiece at an angle, it can be used for the rapid manufacturing of either prototypes or end-use parts. Different to Milling, Turning is another popular service in which a single-point cutting tool is used to cut the workpiece from block or bar materials while it is rotated at speed in a chuck. It is generally used to create round or tubular shapes.

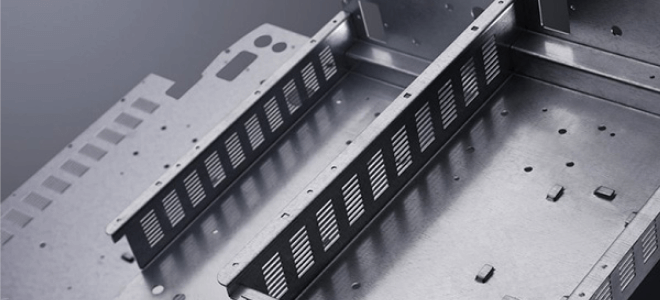

Sheet Metal Fabrication

Sheet metal fabrication is the process of turning flat sheets of steel or aluminum into metal structures or products, by cutting, punching, folding and assembling. Sheet metal can be cut, bent or stretched into nearly any shape, which is generally done by cutting and burning the metal. Materials can be Aluminum, Stainless Steel, Copper, and some other low carbon steel.