RIX CNC Machining

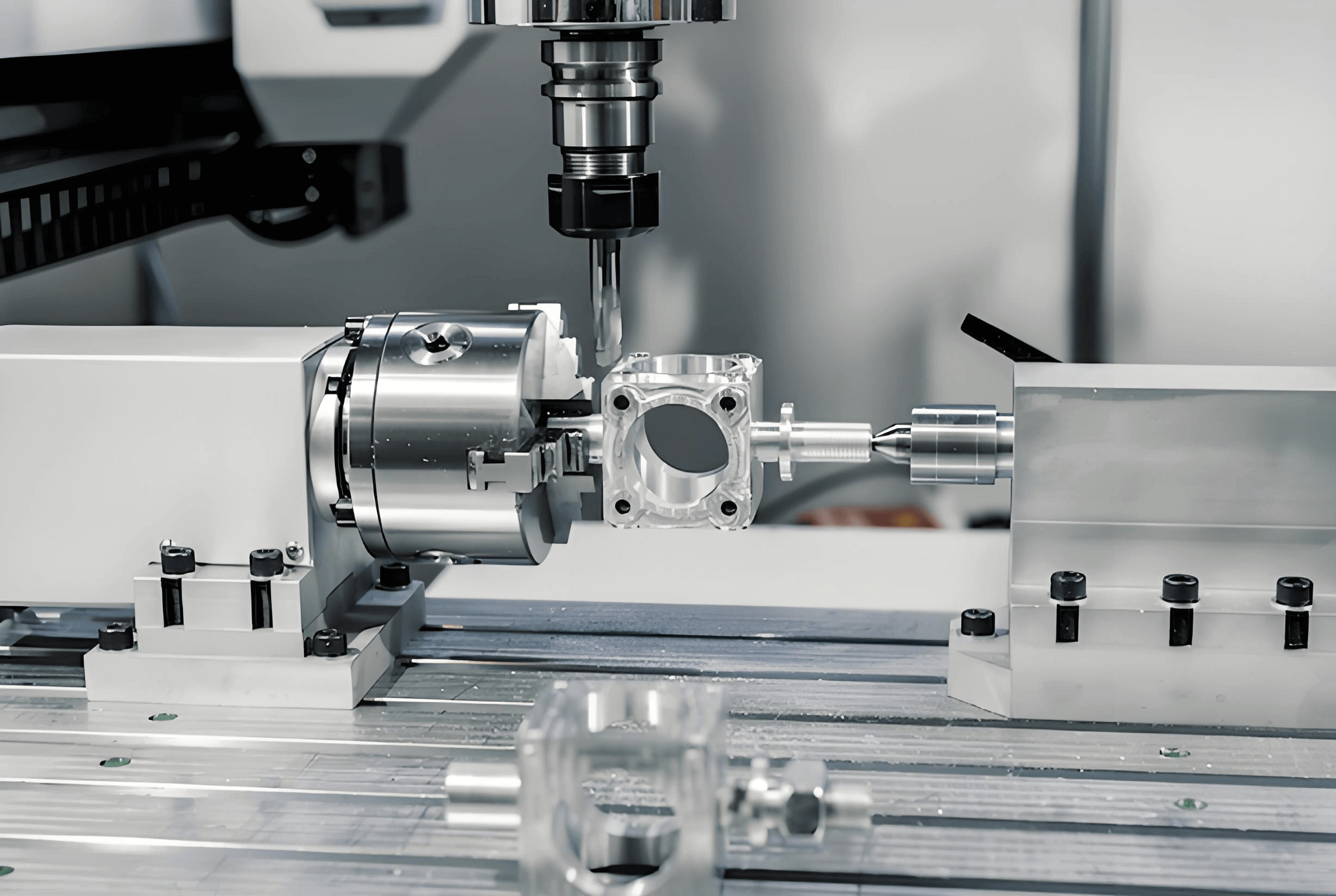

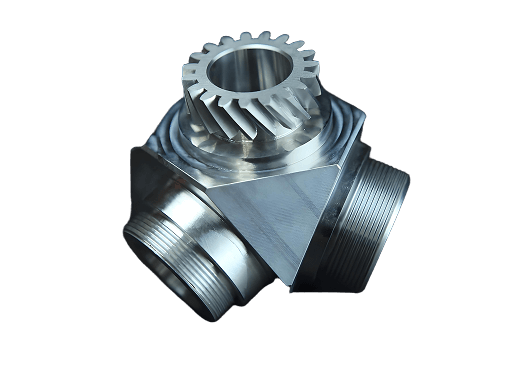

CNC Precision Machining

CNC Precision Machining uses precision CNC machining to manufacture part with strict design specification, critical tolerance and high-demand surfaces. Using 3 to 5 axis CNC machines and professional experiences, we offers high quality precised complex parts, such as automotive engine, housing, hubs etc.

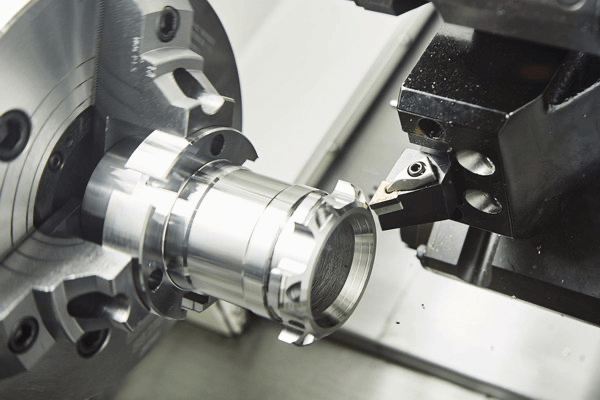

CNC Turning

CNC Turning is the process of removing material from a rotating workpiece using the linear path of tools on a CNC lathe or turning center. Multi-axis CNC Turning centers allow multiple processes and multi-step machining operations on a single machine, making them a cost-effective option for complex geometries.

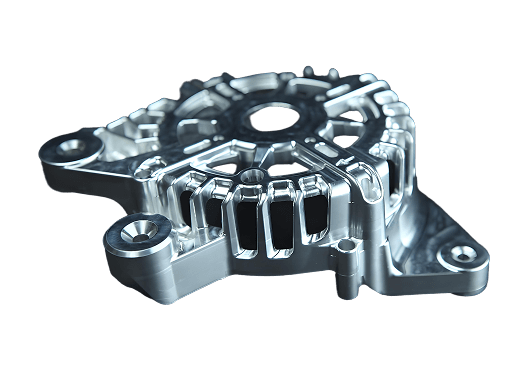

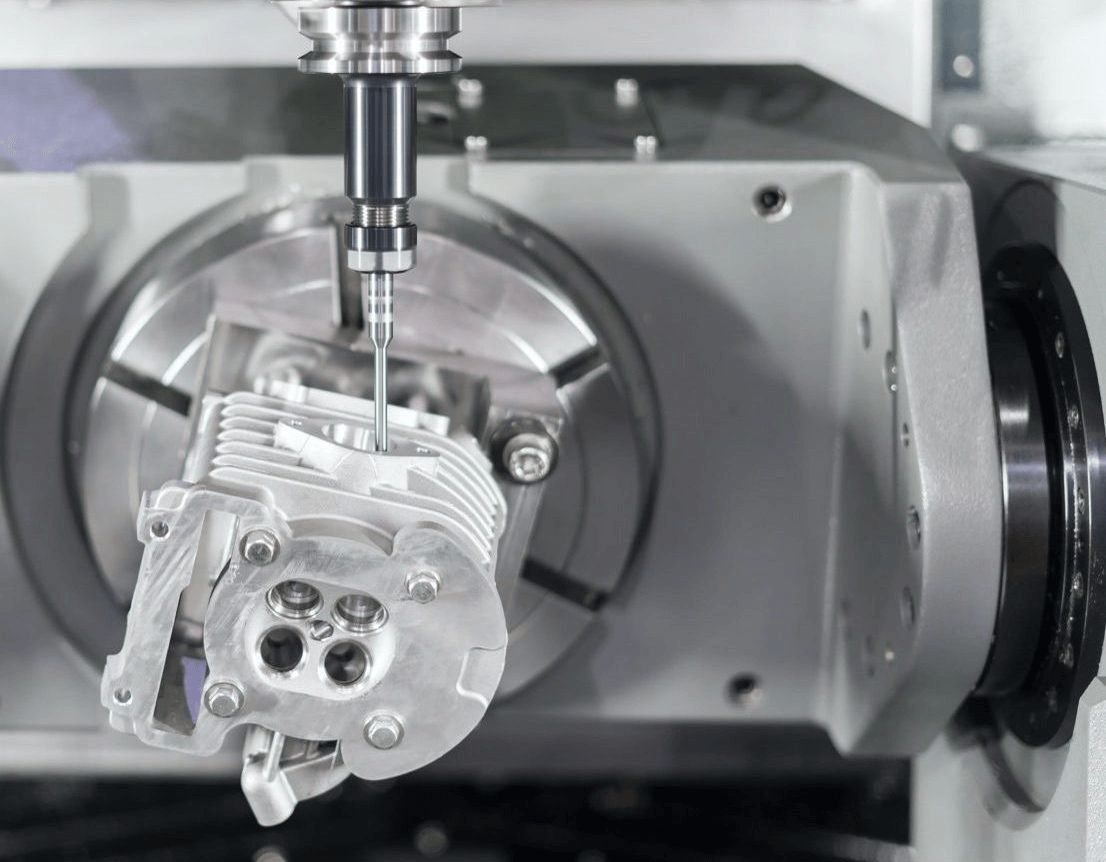

CNC Milling

CNC Milling is a subtractive form of manufacturing that can be used for cutting and machining operations of various plastic and metal materials. Milling is the most versatile CNC Machining process with high adaptability and flexibility. It is suitable for any industry that requires precision components and also an ideal way for making molds.

CNC milled parts can be machined in multiple processes after one set-up; 5-axis CNC Milling can be machined on multiple surfaces at one time.

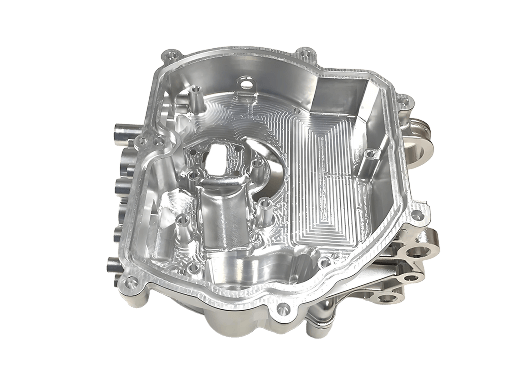

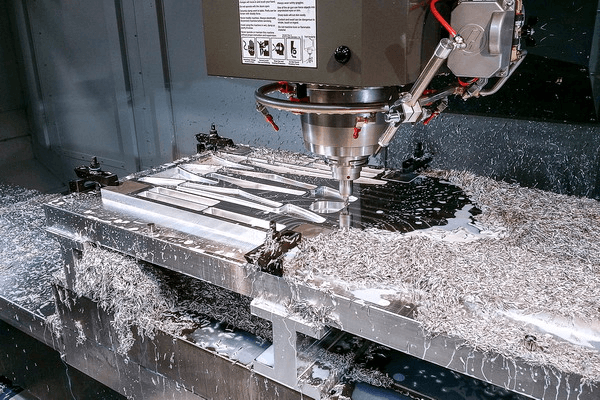

CNC Lathing

CNC Lathing is generally much faster than with a conventional lathe. The needs for modern consumers to be different has led to a greater diversity in product models and therefore smaller batch sizes. The development of the CNC lathe has made this possible. It also led to quality improvement through high accuracy, low rejection, and consistent quality.